PHOTOS of work & finishes used

PHOTOS OF WORK AND FINISHES USED

What follows are some photos of my work along with brief information about the pieces, together with a description of the finishes and the finishing processes used on the items.

Cheers – Neil

Apologies for poor photo quality. many are photos of photos taken back in the mid 80’s and laminated onto card for display. Most taken the mid 1980’s were with cheap and nasty non focusable cameras.

________________________________________

NUMBER 1:

One of three Victorian coats of arms carved for the Victorian Supreme Court, Courts of Appeals, Latrobe St Melbourne. One for each of the three court rooms.

TIMBER: Tasmanian Huon Pine

SIZE: Approx. 85 cm wide x 109 cm high x 60 mm deep

Finish: Sanded to 800 grit. Applied one coat of Sanding Sealer to the entire surface – when dry it was sanded lightly with 1200 grit to remove raised grain – applied a second coat of Sanding Sealer – and when dry did a wipe over entire surface very lightly with 1200 grit to smooth the surface, without allowing the abrasive to cut back through the thin coating of sealer into the surface of the wood – Traditional Wax was then applied with flannelette cloth and a soft bristle, natural colour boot brush (not black bristles) to get into areas that can’t be done with the cloth. Allow to dry tor a few hours then buffed with clean flannelette sheet turning regularly to stop from laying down wax from the cloth that has already been removed.

A second application of Traditional Wax was applied a week later and when dry was buffed off in the same manner as above. No brushing was done on this or the previous buffing. Doing it this way gives a beautiful soft sheen to the finish and allows for more light and shade on the work… IE: there will be a sheen on all the highpoints and a more mat to satin finish in the low parts of the piece.

These 3 coats of arms were carved and installed (from memory) in 1995. Last time seen in 2021 they were still looking great and in no need of refurbishment.

<- CLICK PIC FOR MORE INFO, PICS, ETC.

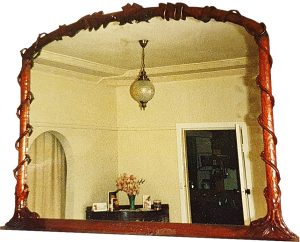

NUMBER 2:

Fully carved, over-mantle mirror for a client. Carving starts as a tree at base on both sides and winds around the frame as a prickly vine that eventually flattens out and transforms into a very fine linen-fold, ribbon across the top.

TIMBER: Philippine Cedar

SIZE: Approx. 2.28mt wide x 1.7mt high x 76mm deep (7’5″ x 5’6″ x 3″)

FINISH: Sanded to 800 grit 1 coat Sanding Sealer sanded with 1200 grit to remove any raised grain, followed by 2 weak brushed coats of shellac followed up with French polished shellac for all areas that had flat or undulating surfaces.

After 1 week lightly rubbed all over with 0000 steel wool then a coat of Traditional Wax left to dry then buffed with clean flannelette sheet, turning regularly to keep a clean piece always working on the buffing up of the wax, otherwise the wax is just being spread over the work again.

<- CLICK PIC FOR MORE INFO, PICS, ETC.

<- CLICK PIC FOR MORE INFO, PICS, ETC.

NUMBER 3:

Carved, ball and claw, tripod pedestal dining table.

TIMBER: Honduras Mahogany

SIZE: 5 foot diametre top, 6inch pedestal, tripod legs outer diametre 4ft 6inches

FINISH: All sanded to 600 grit, then dampened with water to raise grain, when dry sanded with 800 grit to remove raised grain, then chemically dyed with water based potassium dichromate mix to age the mahogany. When fully dried sanded lightly with 1200 grit then a ragged on application of Sanding Sealer. No colour matching was required so the entire table was French polished.

Around 20 applications in short bursts over a few hours. Next day another 20 or so applications of the same using paraffin oil (Food Safe Plus) as a lubricant. Day 3 few applications of French polish then then spirit off the oil and finished.

Total time French polishing over 3 days… no more than about two and a half to three hours tops.

Left for a couple of weeks then a wipe over the top with Polish Reviver on an off, to protect the surface from heat, alcohol, finger marks, water, etc.

NUMBER 4:

A variety of turned bowls for decorative finishes exhibition for state festival

TIMBER: A: Canadian Birdseye Maple B: Qld Maple C: Cedar of Lebanon D: Redgum Fence Post and Canadian Birdseye Maple with redgum inlay. E: 2 miniatures in Applewood F: WA Lace Sheoak with Huon Pine lid with sheoak insert G: Yellow Box Burl H: American Hardrock Maple.

SIZE: Platter C: is 61cm (24 inch) dia. Might need a bit of imagination to work out the rest.

E: The almost invisible wine goblet is approx. 2mm dia. x 4.5mm high.

FINISHES: Various… A: Red Water Dye with silver inlay, EEE-Ultra Shine, Shellawax.

B: Red Water Dye, EEE-Ultra Shine, Shellawax Glow.

C: Decorated rim, Talc and PVA glue stippled Gesso effect, White Shellac and green universal stain painted over the gesso and when dry lightly buffed back with 0000 steel wool to bring out the stippled pattern. the rest finished with 1 weak coat of White Shellac ragged on to the surface then Waxtik over the top buffed with clean soft cloth whilst lathe is running.

D: Redgum fence post exterior all finished with Shellac. The bowl, internal, rim and lid all done with EEE-Ultra Shine then Shellawax 2 coats no sanding between and done one on the other within a couple of minutes.

E: No finish other than very sharp tools, super clean, smooth cuts and a heap of experience.

F: EEE (1 application) and Shellawax.

G: EEE (1 application) and Shellawax Glow 3 coats. Gesso decorated edge (same as C above) regular shellac and deep red universal tint (red with s little black mixed in) Not rubbed back with steel wool.

H: Same as gesso effect as (G below left) with less black in the red and rubbed back with 0000 steel wool when dry. EEE (1 application) and Shellawax 3 coats.

CLICK PIC FOR MORE INFO & PICS, OF DECORATIVGE FINISHED FOR WOODTURNERS

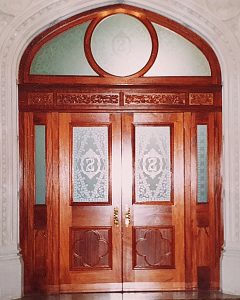

NUMBER 5:

Carved transom panels above doorway from the floor of the Old Stock Exchange to the ANZ bank chambers, part of the ANZ Bank complex. Cnr. Queen and Collins St Melbourne.

Top photo: is one of 8 panels (4 large and 4 small) for above both sides of internal doors. The panel is fully carved sanded and ready for finishing.

Bottom Photo: is of the internal doors finished with the transom panels in place looking from Stock Exchange towards the bank on the other side of the doors.

SIZE: Long panels: 1mt x 23cm each.

Short panels: 470cm x 23cm each

The above are approximate sizes edge to edge

TIMBER: African mahogany was specified but I reckon it was Brazilian Mahogany.

FINISH: These doors and panels were all “supposedly” French polishes by the client who commissioned me for the work. However I would say it looks more like they were sprayed with multiple coats of orange shellac.

_______________________

NUMBER 6: Stock Exchange External doors Collins St entrance

TIMBER: African mahogany was specified but I reckon it was Brazilian Mahogany.

SIZE: Wooden section only 3.25MT high x 2.26MT